Cast glass transforms glassmaking into a captivating art form by melting glass and skillfully pouring it into intricate molds.

This innovative process unlocks a world of unique textures, mesmerizing patterns, and stunning three-dimensional shapes that flat glass simply can't achieve.

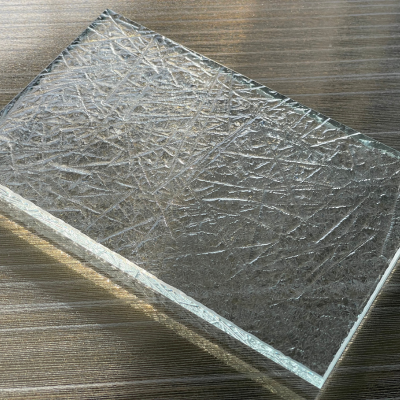

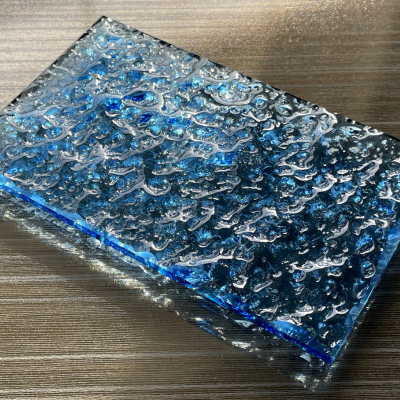

As the molten glass settles into the mold, it adopts beautifully textured or sculpted surfaces, ranging from delicate, subtle nuances to bold, dramatic reliefs.

The result is dynamic interplay of light and shadow, creating visually striking effects that bring architectural spaces to life with depth and character.

Common Applications of Cast Glass

Wall Panels and Partitions Cast glass panels create stunning visual dividers, adding texture and light play to interior spaces. They can be used for privacy while still allowing light to pass through.

Doors and Entryways Class glass doors make a grand statement, crating a memorable first impression. They can be designed with intricate pattenrs or bold textures.

Facades and Exterior Cladding Can be used for exterior applications, although careful consideration must be given to weather resistance and structural integrity. It can add a unique and artistic element to building exteriors.

Lighting Fixtures Create unique and sculptural lighting elements, diffusing light in interesting ways.

Sculptural Elements and Artwork Create standalone art pieces that are integrated into architectural spaces. This can include sculptures, screens, or other decorative elements.

Stair Treads and Landings With appropriate reinforcement, cast glass can be used for stair treads and landings, creating a dramatic and modern effect.

Countertops and Tabletops Cast glass offers a unique and durable surface for countertops and tabletops, adding a touch of artistry to functional elements.

Beyond these applications, our expertise in manufacturing allows us to realize your designs and make them a reality.

Let’s do this together!Customization Options

Texture & Pattern

The mold determines the texture and pattern of the glass.

This allows for an almost limitless range of designs, from subtle ripples to deep, sculptural reliefs.

Size & Shape

Cast glass can be produced in a variety of sizes and shapes.

Although very large pieces may require specialized equipment and techniques.

Backlighting

Backlighting can dramatically enhance the visual impact of cast glass, highlighting its texture and color.

Color

Color can be introduced during the melting process by adding metal oxides to the glass batch.

It can also be applied later through techniques like painting, enameling, or fusing colored glass pieces to the cast glass.

Finishing

The finished cast glass can be further processed through techniques like polishing, sandblasting, or acid etching to achieve different surface finishes and effects.

Lamination

For safety and structural purposes, cast glass can be laminated with other layers of glass or other materials.

GET IN TOUCH